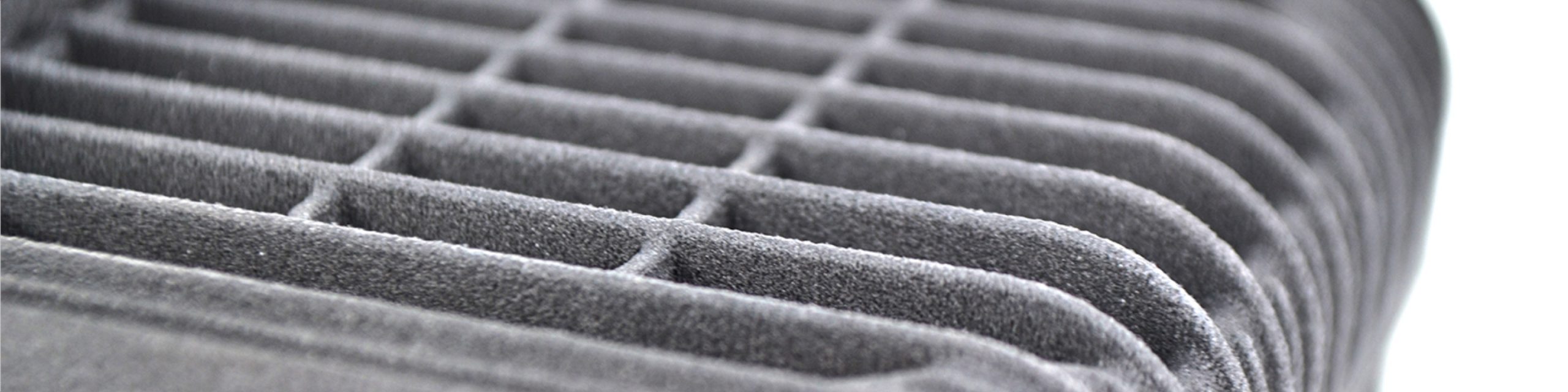

FS3400GF is a nylon grade filled with glass bead. It produces graininess surface, high hardness and good toughness suitable for automotive industries.

Off White (as printed)

Off White (as printed)

Bounding Box Max

400 x 400 x 460 mm

Bounding Box Min

"X + Y + Z > 9 mm 0.5 x 0.5 x 0.5 mm"

The bounding box is a 3D imaginary outline of a box that encloses the smallest area occupied by your model. Your model must be within the minimum and maximum bounding box sizes. If the size of the model is close to the maximum bounding box, then the printing orientation will be restricted.

Interlocking

Yes

Enclosed

Yes

Max

Up to 250

We use cookies to offer you a better browsing experience, including personalized advertising. By continuing to use the site you agree to their use.

Learn more